The Cape Support series as a power barge can be integrated with low-emissions mobile power plants, suitable for temporary electricity and quick power deployment in coastal areas. Depending on the amount of liquid being carried, these power barges can float on the water at around 6.8m draft. They can also be relocated upon the project completion or at the end of contract. Thereby, it can reduce land acquisition issues and reduce site construction costs.

We offer flexibility in power configuration. The Cape Support series as a power barge can be configured with one of the following mobile power plants at either 60, 100, or 120 MW:

See how the Cape Support series as a power barge can provide benefits and solutions for electricity installation projects.

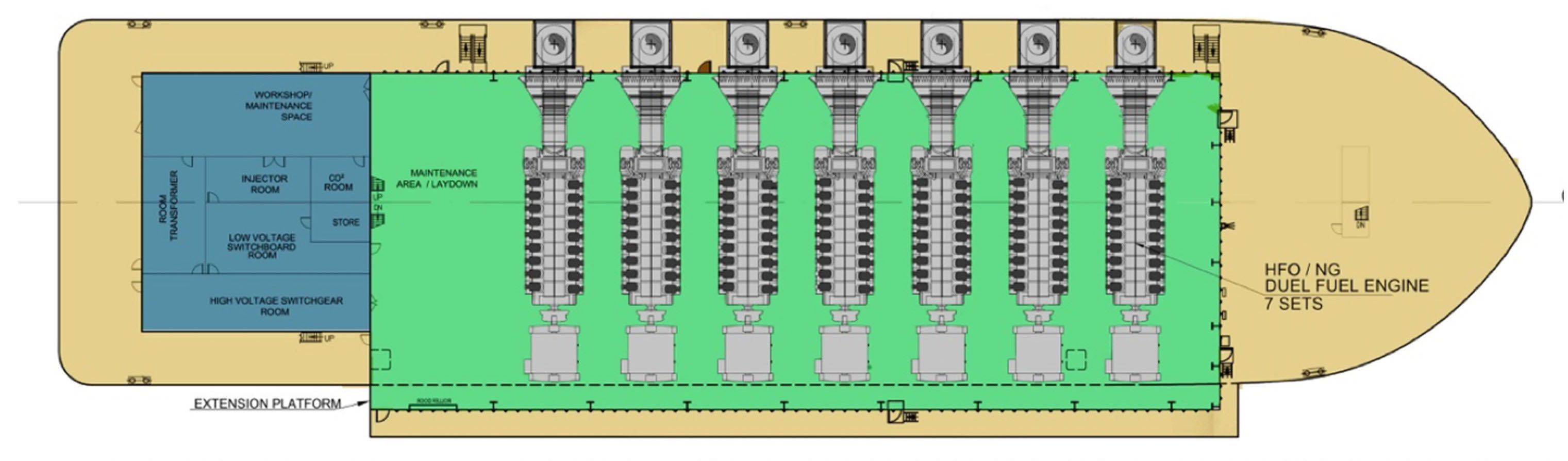

Dual-Fuel Engines Configuration

Dual-fuel engine gives full-flexibility as it can be suitably switched from gas mode to liquid fuel mode. Dual-fuel engine is known for its high-efficiency (about 45%) and ability to produce clean combustion when running on natural gas. The engines’ integration with the Cape Support 1 barge will lead to optimised, environmental-friendly, and low-cost electricity production.

Download the General Arrangement Drawing of Dual Fuel Generator Installation:

– GA 60MW Dual-Fuel Generator (926 KB, PDF)

– GA 100MW Dual-Fuel Generator (897 KB, PDF)

– GA 120MW Dual-Fuel Generator (1.4 MB, PDF)

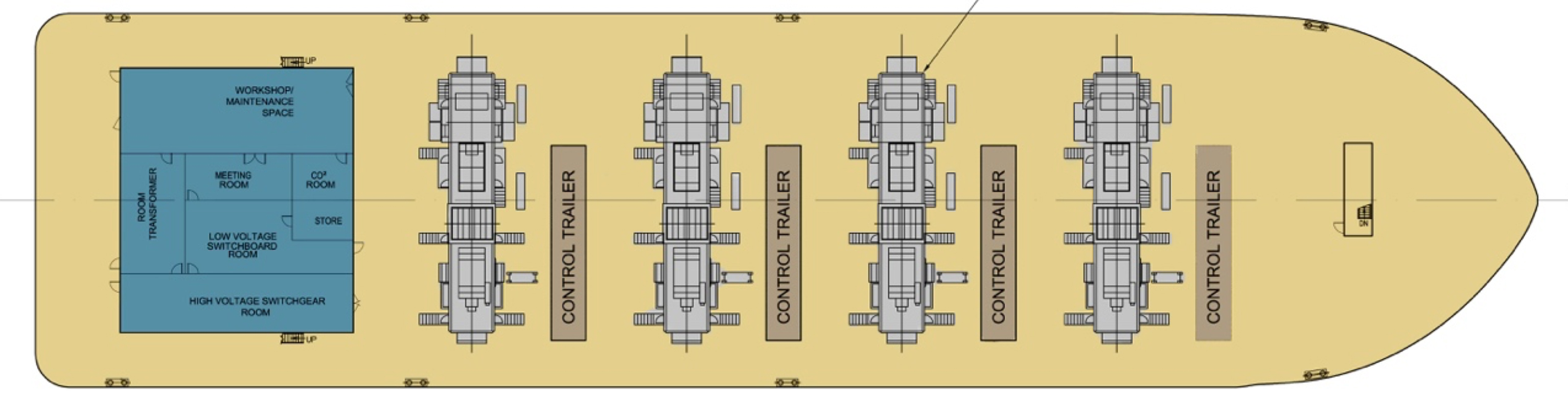

Mobilepac Turbines Configuration

The Mobilepac Turbine by Pratt and Whitney Power Systems is a mobile, environmentally compliant, and cost-effective aero-derivative gas turbine. It is very suitable for the Cape Support 1 power barge due to its size, weight and quick installation time. The deployment of a 120 Mobilepac turbine configuration is even faster than the deployment of a 120 dual-fuel engine configuration. So this type of power plant configuration can be a favorable option for more urgent electrical installations.

Download the General Arrangement Drawing of Mobile Gas Turbine Installation:

– GA 120MW Gas Turbine Power Barge (1 MB, PDF)

Benefits

We provide a fast solution to meet your emergency electrical needs

| 120 MW ENGINE CONFIGURATION | 120 MW TURBINE CONFIGURATION |

|---|---|

| 9-12 months delivery | 3-6 months delivery |