Repeatable float-over installation barge

From 2008-2013, the barge was on charter to an International Oil Company operating in offshore Sarawak, Malaysia. It was part of a turnkey solution in the installation of customised jackets and topsides designed to be installed by the Daiho II over marginal fields. The combination of the lightweight, low-cost topsides/jackets and the Daiho II technique allowed the oil company to maximise their return on investments from these marginal fields over conventional solutions.

The Daiho II has the capability of installing jackets up to 60m water depth and topsides of up to 1,500t utilising the float-over technique without the use of heavy crane.

Explore Daiho II:

1) Barge Specification, Features and Capabilities

2) Track Records

Barge Specification, Features and Capabilities

Classification: Barge ABS + A1

GRT/NRT: 4760T/1428T

Year: 2007

LOA: 100.584m

Beam: 30.48m

Draft: 4.5m

Deck strength: 20T/m

Daiho II

Daiho II

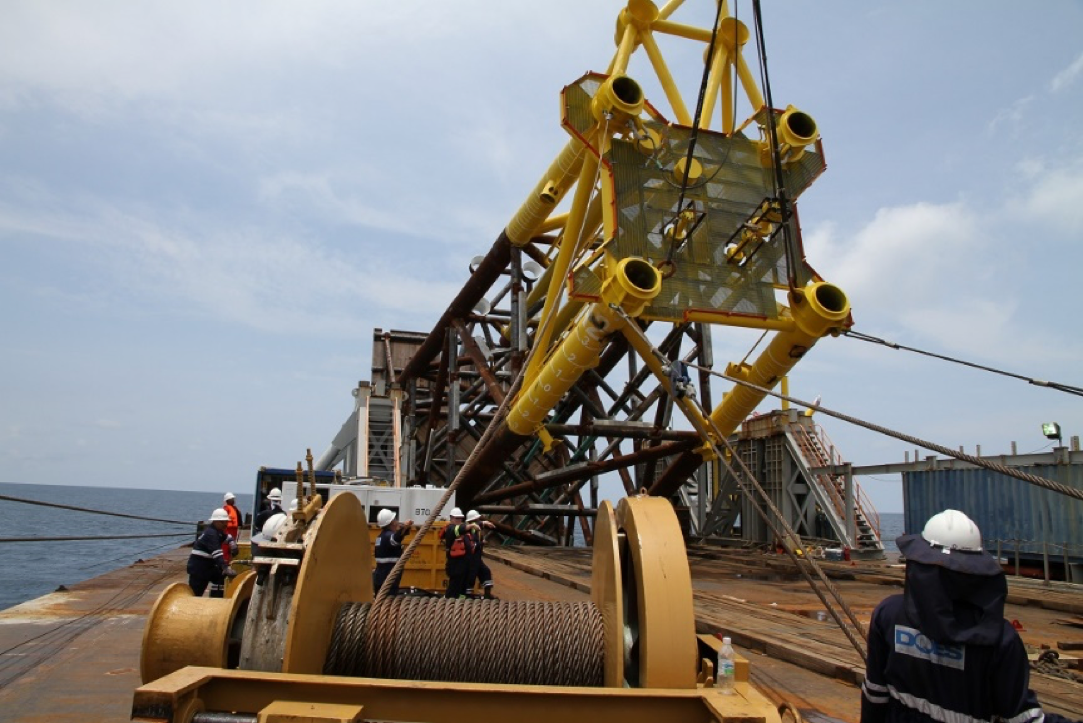

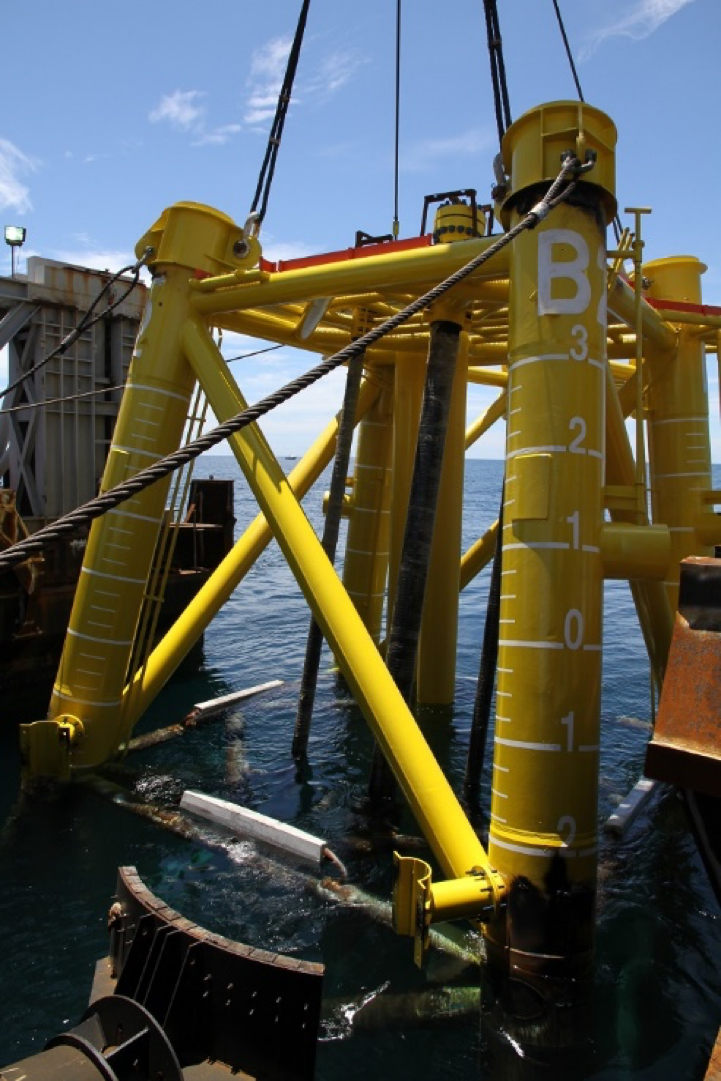

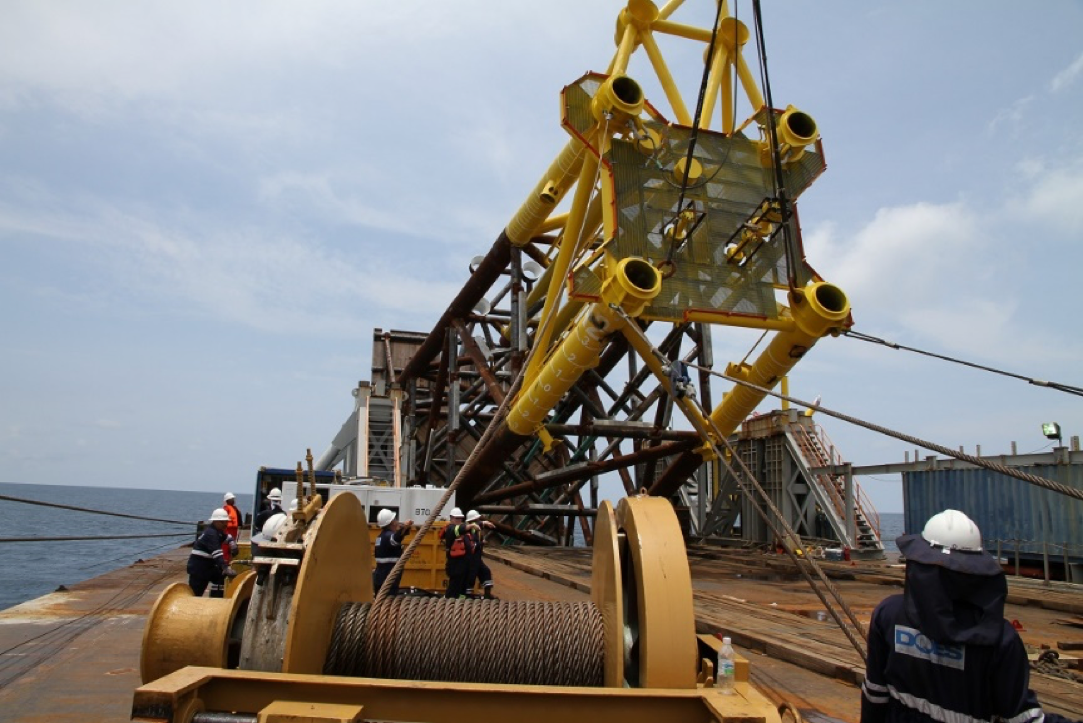

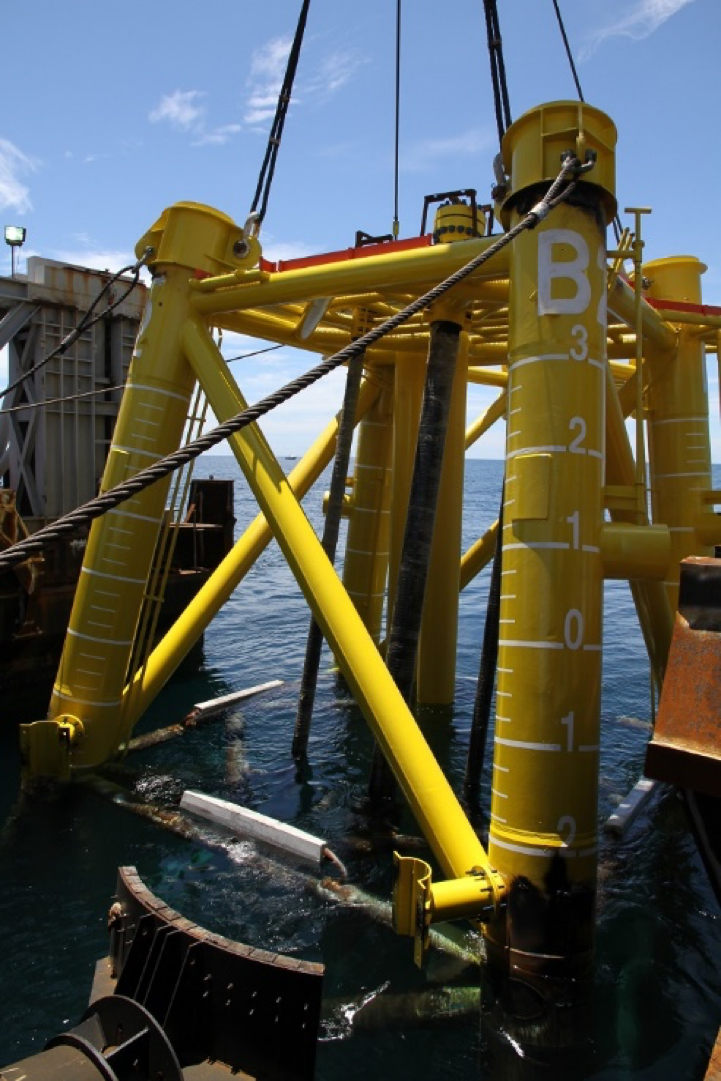

Jacket Installation

Jacket Installation

Jacket Installation

Jacket Installation

Float-over method

Float-over method

-

Daiho II

The world’s only repeatable float-over installation barge for topsides and jackets over marginal fields -

Daiho II

The world’s only repeatable float-over installation barge for topsides and jackets over marginal fields -

Jacket Installation

With the aid of a conventional crawler crane, Daiho II is capable of installing jackets of up to 600T, up to 60m water depth -

Jacket Installation

With the aid of a conventional crawler crane, Daiho II is capable of installing jackets of up to 600T, up to 60m water depth -

Jacket Installation

With the aid of a conventional crawler crane, Daiho II is capable of installing jackets of up to 600T, up to 60m water depth -

Jacket Installation

With the aid of a conventional crawler crane, Daiho II is capable of installing jackets of up to 600T, up to 60m water depth -

Float-over method

Using the float-over method, the Daiho II is capable of installing platforms of up to 1,500 T. -

Float-over method

Using the float-over method, the Daiho II is capable of installing platforms of up to 1,500 T.

Track Records

Jacket Installation

| Year | W.Depth | Weight |

|---|---|---|

| 2009 | 65 m | 600 MT |

| 2010 | 32 m | 450 MT |

| 2011 | 32 m | 450 MT |

| 2011 | 35 m | 480 MT |

Topside Installation

| Year | Capacity | Weight |

|---|---|---|

| 2008 | RISER HUB | 550 MT |

| 2009 | GAS PLATFORM: 155 MMCF/D | 1,250 MT |

| 2009 | GAS PLATFORM: 155 MMCF/D | 1,250 MT |

| 2010 | GAS PLATFORM: 155 MMCF/D | 1,250 MT |

| 2013 | GAS PLATFORM: 155 MMCF/D | 1,350 MT |

We do not disclose further information on our track records on this website due to privacy reasons. Nevertheless, do not hesitate to contact us for more details about our company and track records.